Printing worthy of an Oscar – with the oscar3D premium nozzle.

Unbeatable in price & performance.

The newest: Based on countless user feedback and over two years of market analysis, we have completely revamped our oscar3D – the next generation is here. With a revolutionary price and performance. Premium technology with the red ruby and super-precise drilling.

Now available for the unbeatable price:

oscar3D from €39.99 – oscar3D Pro Stainless Steel for €89.99 – Oscar 3D Pro S5 for €99.99.

Order it now on Amazon:

Black Forest precision

For over 120 years, we here at Oskar Moser in Elzach in the Black Forest have shown how creative minds and experienced hands can create true miracles out of ruby. The focal point is always the technical gemstone. Due to its outstanding material properties, it is a true all-rounder ideal for many applications and uses.

Oskar Moser is a well-known specialist for brilliant technology and customised precision nozzles. We offer a broad range of products – from cleaning nozzles, jet nozzles to special laboratory and medical technology applications. Last but not least: nozzles for 3D printing: oscar3D. Do you need a custom solution? No problem, we develop and design in house the perfect nozzle for any requirement. What is your next project?

Precision meets brilliance - premium 3D printing nozzle for flawless masterpieces

oscar3D: Special features of our 3D printing nozzles:

- High precision: Nozzle bore with 10 µm tolerance

- Super fast: Ultra heat-conductive brass

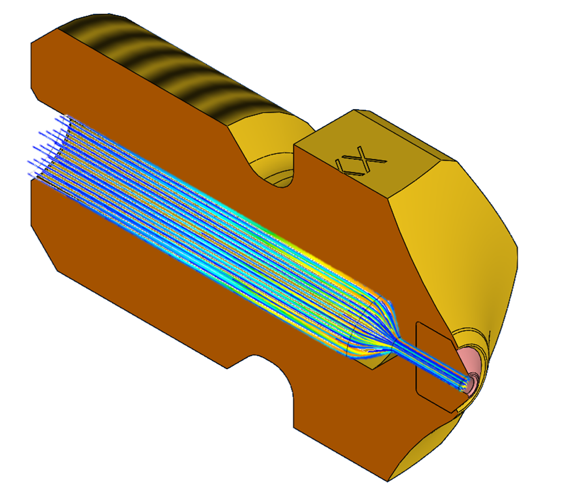

- Optimum flow: Nozzle channel free of turbulence

- Highly heat-resistant and durable: Form-fitting ruby bezel

- Clean & easy to maintain: Exquisitely polished surface

- Connector-friendly: standard for 3D printer with E3D-Hotend, MK8, MK10

The perfect character

oscar3D offers the perfect characteristics and technical equipment for premium-quality 3D printing.

Guaranteed nozzle diameter

For each nozzle, we guarantee the most precise nozzle diameter (featuring a tolerance of just +10µm to the nominal size) available on the market.

Top design

oscar3D consists of 2 parts: Ruby tip and nozzle body. Each variant has a separately adapted nozzle body. This requires more effort however it provides more benefits. For example: no dead spaces, no insulating air pockets between the components as well as a more stable thread profile.

Optimal heat flow

There is no question that ruby serves as an insulator. Together with the design referenced above and a tightly entwined rim inside of the nozzle body, this results in an optimal thermal flow all the way to the nozzle tip.

Polished nozzle tip

With the help of a diamond grinding paste and a soft cotton polishing wheel, each nozzle tip is highly polished, cleaned, degreased and placed in the packaging by hand using gloves. This allows the nozzle to be cleaned externally using a paper towel and it also minimises material deposits.

For ambitious DIYers & professionals

Our nozzle portfolio leaves nothing to be desired with the oscar3D in brass and the new oscar3D Pro in stainless steel for professional industrial applications. oscar3D allows you to meet all of the requirements of high-quality 3D printing. You can find the respective technical specifications in our "Variants" product table.

Proven quality

We place a major emphasis on craftsmanship. Defined processes ensure safety and our 100% outgoing goods inspection guarantees that each nozzle meets our high quality standards.

oscar3D – for premium quality 3D printing

For flawless components and wear-free printing of abrasive filaments. Guaranteed! Proven thousands of times over. The measuring stick for Oscar-worthy printing.

oscar3D Pro in stainless steel – for the highest industrial demands

Made of robust, highly heat-conductive stainless steel – especially durable and thermally stable. The professional nozzle for industrial applications.

Expertise makes everything better

The topic of FDM 3D printing is very complex – here is an in-depth look at the technical details.

Our entire day revolves around nozzles, which is why we know: A profound technical background gives you a decisive edge. That is why we want to:

- share our experience with you

- offer tips and tricks for working with oscar3D ruby nozzles

- resolve questions ahead of time

- offer a greater understanding of how 3D nozzles work

Ruby is a technical gemstone with outstanding material properties:

- one of the world's hardest materials

- extremely wear-resistant

- ideal for metal as well as carbon-filled filaments

- brass or steel tips dissolve after a few hundred grams of abrasive material but the ruby tip from oscar3D holds firm when used correctly

- the nozzle remains stable even after several kilos of material have been applied – no need to readjust the nozzle distance and no need for a replacement

- Obviously, nothing lasts forever. After approx. 300-500 hours of printing (average figure based on practical experience), a replacement is recommended to maintain an optimal print image

Below you will see the results of a tensile test. Here, using the same settings, samples were printed and then examined with regard to their strength. First using an ECO and then a VARIO. In this case, an average increase of strength of approx. 6% was achieved.

It should be noted here that the objective was merely to establish the difference between ECO and VARIO prints with regard to the increase of their component strength when using the same settings. The ECO can definitely achieve higher component strength increases if the printing parameters are optimised in that regard. For example, this can be achieved by changing the so-called "extrusion multiplier", which can be used to further increase the material flow and allows print webs to bond better.

- Printer: PRUSA I3 MK3

- Material: ColorFabb XT CF-20

- Nozzles: oscar3D ECO SS 1.75mm 0.4mm

- oscar3D VARIO SS 1.75mm 0.4mm

- Heated bed temperature 90°C

- Print head temperature 275°C

- Layer thickness 0.15mm

- Filling 100%

- Tensile test according to DIN EN ISO 527-2:2012-06

- Test specimen Type 1B

- 5 specimens for each nozzle variant

- ECO: 30.3 MPa, 76 MPa according to the manufacturer

- VARIO: 28.9 MPa, 76 MPa according to the manufacturer

Upon request, we will gladly send you detailed reports of the tensile test.

If the nozzle clogs despite the correct conditions of use, we recommend cleaning it using the so-called "cold-pull process", which consists of the chemical loosening of the material, or via chemical cleaning with special cleaning needles. Since ruby is a very spry material, in order to prevent spalling at the tip of the nozzle, the utmost care is required when carrying out mechanical cleaning using a needle. We never recommend cauterising the nozzle over an open flame.

Please take your time to get to know your oscar3D. It’s the same with every new product you use: whether it is a new PC, a home cinema or a new car – you don't go all out right away, opening every programme at once. Instead, you carefully explore the new technology.

Printing enhanced (and in particular fibre-filled) filaments poses a special challenge because the nozzle tends to be clogged in these cases or does not supply the desired printed image. The reason is that the filament contains special additives!

Printing fibre-filled filaments is especially tricky, because, for example, the length, thickness, quantity, distribution and quality of fibres in the filament string influence the flow behaviour in the liquefied filament in the nozzle a lot. It is possible that the flow behaviour appears to be inhomogeneous or that the nozzle clogs completely.

That is why we recommend that you initially proceed with care when printing using fibre-filled filaments and, after installing an oscar3D, that you first use conventional materials such as PLA or PETG to gain some experience.

Generally, due to the insulating effect of the ruby, we suggest to operate the nozzles at a temperature of 10°C – 20°C higher than the melting point recommended by the manufacturer of the filament. In addition, the print speed during the first attempts should not be greater than 40 mm/s in order to ensure a good fusing of the material.

The oscar3D is designed for the so-called "E3D-Hotend", which has become the standard. However, the nozzle can also be installed in printers without an original E3D-Hotend. It is possible that slight adjustments have to be made at the printer – for example by offsetting the Z-Stop sensor – or the nozzle has to be machined – for example by using a lathe.

Email us for detailed technical drawings: We will gladly send you the information.

Order now

oscar3D allows you to take full advantage of everything 3D printing has to offer – with outstanding premium quality. As a manufacturer of precision nozzles, we are also expert innovators: What can we develop for you? Challenge us!

For manufacturers and wholesale customers

It takes just one e-mail! We will contact you immediately with an attractive offer.